Gaznat’s main job may be supplying and transporting high-pressure natural gas to western Switzerland, but the company is also working on ways to contribute to the energy transition and help decarbonise society through innovative projects to develop new technologies. “Our vision is to be able to supply carbon-neutral gas by 2050,” says Network Director Gilles Verdan. “The Swiss Gas Industry Association has even set itself the objective of producing 30% of gas for heating from renewable sources by 2030.”

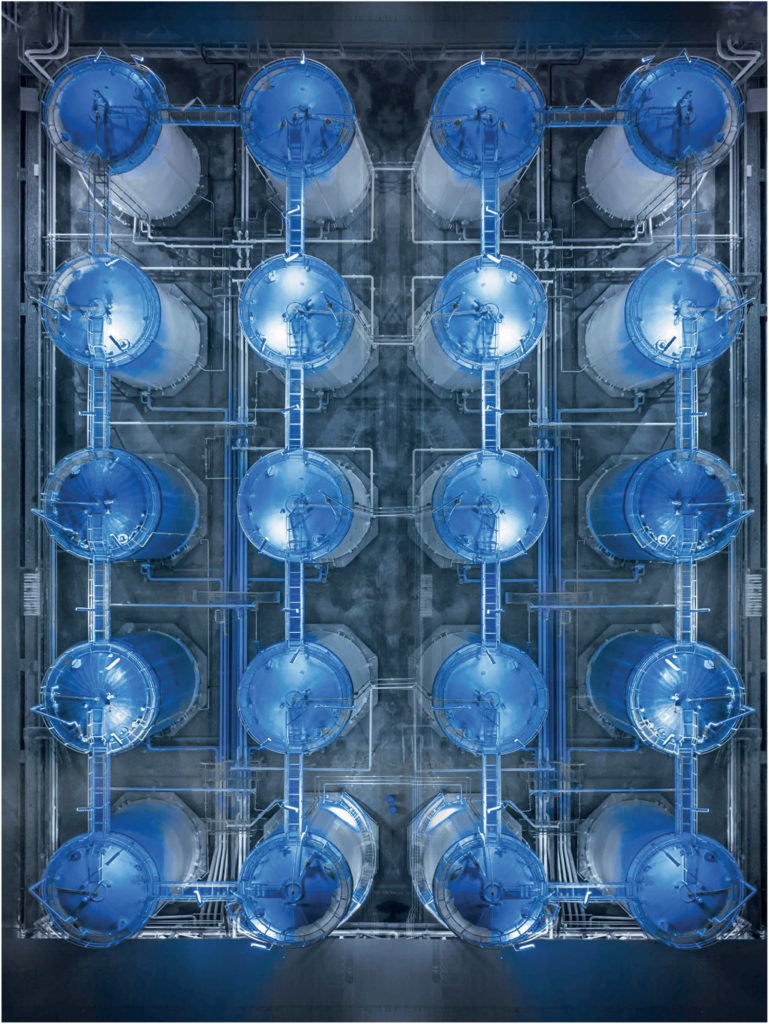

To contribute to the decarbonisation of the gas industry, in August 2023, Gaznat opened its Innovation Lab on the site of its Dispatching Centre in Aigle. It is now testing two major mature innovations on an industrial scale there: a methanation reactor and CO2 capture membranes. These have been developed by scientists at the Swiss federal institute of technology EPFL Valais-Wallis, not least thanks to Gaznat’s funding of three chairs and 16 separate projects in these areas.

A conversion rate of nearly 100%

The methanation reactor, currently at the pre-industrial testing stage, has a thermal power output of 225 kWh. It produces carbon-neutral synthetic methane which is identical in every respect to the natural gas circulating in the country’s pipelines. This technology is also set to provide a seasonal storage solution for excess electricity production. This is because the hydrogen required for the methanation process is produced from renewable energy sources, which means that the summer surplus of solar, wind and hydraulic electricity can be re-used in the form of methane. The CO2 used in the process is captured on industrial sites in Switzerland. “Our methanation reactor has an excellent CO2 conversion rate – greater than 99%,” says Gilles Verdan.

The second area of development provided by the Innovation Lab is the use of graphene nanopore membrane technology to capture the CO2 emitted by the site’s two combined heat and power installations. This innovation has the potential to help neutralise the high levels of CO2 emissions produced by certain industrial activities. “If we want to achieve the carbon neutrality goals, it is crucial that we roll out carbon capture technologies,” he says.

A regional testing platform

The Innovation Lab may have been developed specifically to test these two technologies, but it is also set to become a testing platform for projects investigating energy issues being studied at EPFL, along with universities and start-ups around the region. “Scientists need to be able to test their innovations in an industrial setting,” says Gilles Verdan. “On our site, we have room to accommodate them, and we can provide all the energy carriers too.” The projects funded by Gaznat and tested on the site are all aimed at commercial production.

Gaznat SA