Meyer Burger was founded in 1953. In 2021, it became the only manufacturer of solar cells on the market outside Asia. The company has 1500 staff members and production plants in Switzerland, Germany and now also in the US. Research and development are still based entirely in Switzerland.

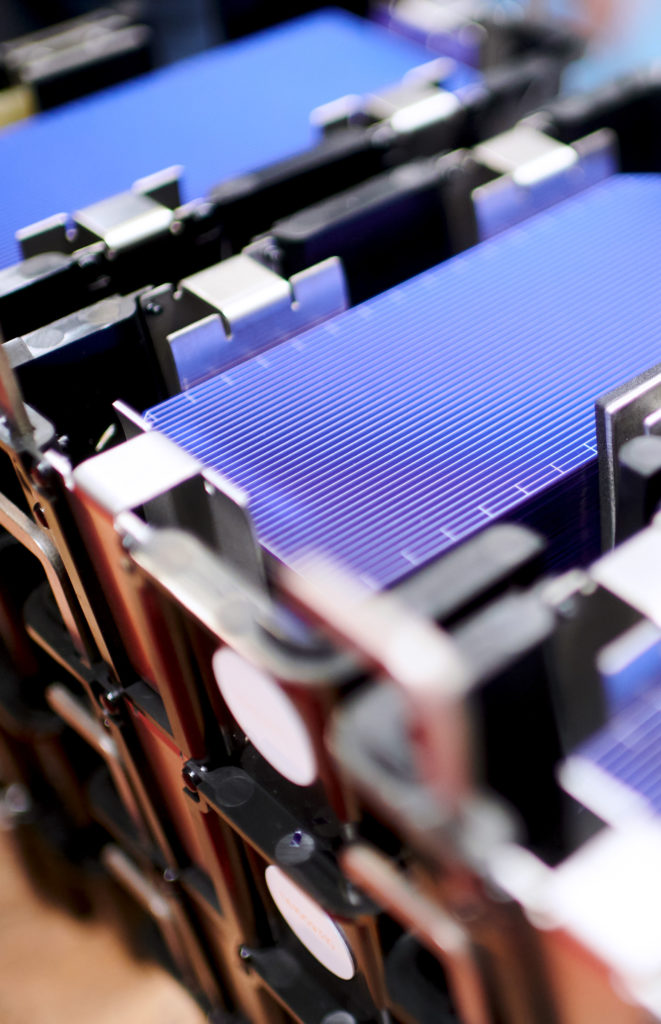

Together with Swiss innovation specialists CSEM, and with the support of the Federal Office of Energy, Meyer Burger has developed a new technology for solar cells and modules. This combines two types of silicon into one junction (known as a heterojunction). The electrical contacts – the company’s patented SmartWire technology – are placed on both sides of the solar cell, which enables very efficient bifacial use in the glass-glass module. However, Meyer Burger’s most significant innovation is its drastic simplification of the manufacturing process, which allows this new technology to be competitively produced on a large scale.

The company is making great efforts to limit the amount of silver used to produce the modules and to replace it completely in the future. This should reduce manufacturing costs while also conserving a resource and avoiding any supply bottlenecks in a metal that is widely used in the photovoltaic industry.

Meyer-Burger modules with heterojunction/SmartWire technology are particularly durable, as are the products in the next innovation step: back-contact solar cells. These enable even higher energy yields on the front surface, as the connecting wires no longer ‘shade’ the solar cell in this area. Efficiencies of over 25 percent have been achieved with this in the laboratory, which means that more than a quarter of the solar energy is converted into electricity. The target date for the start of volume production is 2025.

At Meyer Burger, it is not only module technology and the manufacturing process that involve innovative thinking but also product design. The company has been producing solar roof tiles in volume since 2023. These are recommended for roofs that are obstructed by dormers or chimneys, and for listed buildings. A slate-grey variant has already been added to the colour range to give builders and architects greater aesthetic scope.

Meyer Burger intends to consistently exploit the growth opportunities in the photovoltaic market with its solar modules: by 2026, production capacities should be five times greater than in 2023, increased to seven gigawatts a year. And, thanks to its highly automated production lines, the company is proving that European module production is globally competitive.

Meyer Burger Technology AG